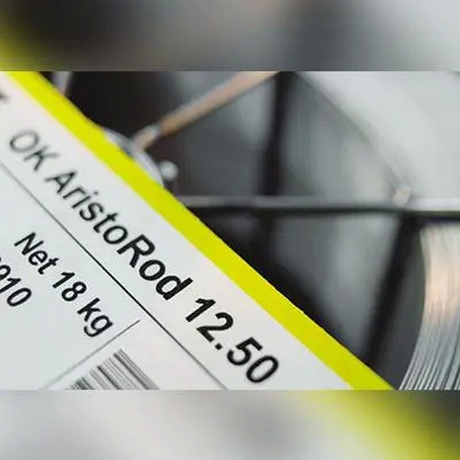

OK AristoRod 12.50 ER70S-6 / G3Si1

Non-copper wire for MIG/MAG welding in CO2 shielding or CO2/Ar mixture of unalloyed structural steels, ship and boilerplates, and pipe steels. The unique coating technology enables extremely stable work with high welding currents, high-quality wire addition without downtime with reduced addition force, reduced wear of consumable parts, and significantly reduced spattering, which sets this wire apart from classic copper-plated welding wires. Copper dust, in addition to settling in the guide and the gun over time, also affects the stability of the arc, which can directly affect increased spatter. As a consequence of increased spattering, in addition to unnecessary material, there is also the need to process the welded joint after the welding process (grinding). OKAristoRod 12.50 enables a consistently clean bolted joint without cracks and requires subsequent processing. In addition, reduces moisture absorption and the risk of corrosion. Fumes are an inevitable part of the welding process. It is minimized, and these fumes do not contain copper, which creates better working conditions and reduces pollution. The best performance is achieved with a manual or mechanized welding process using a gas mixture (Ar18%CO2). Approvals: ABS, BV, DB, DNV, GL, LR, TUV.