SMART fiber lasers – compact and economical metal cutting machines

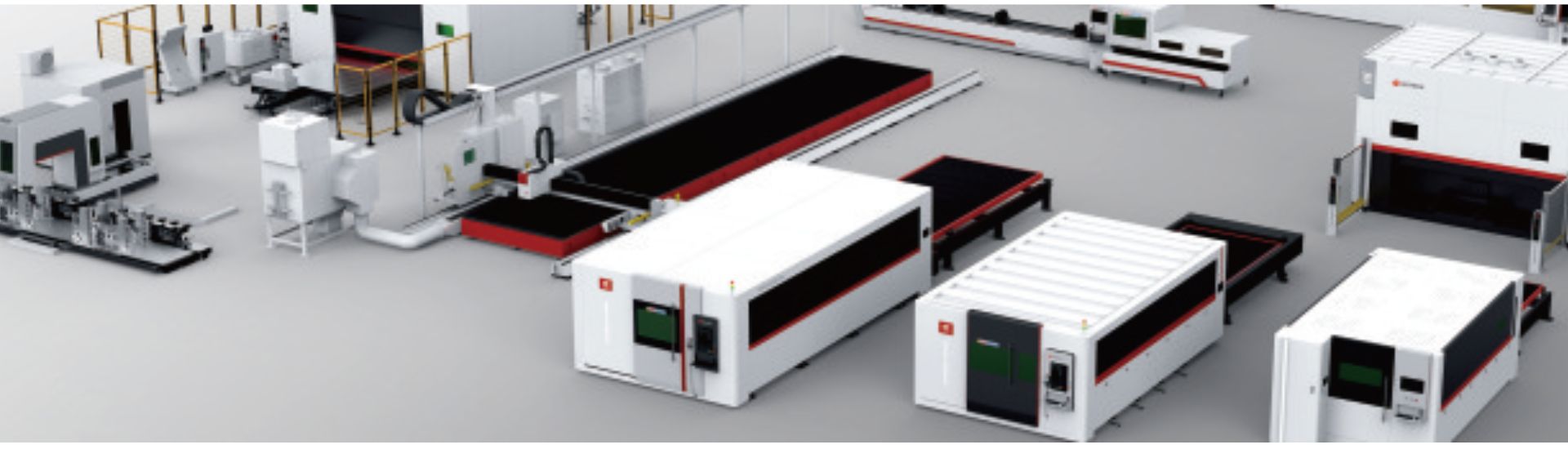

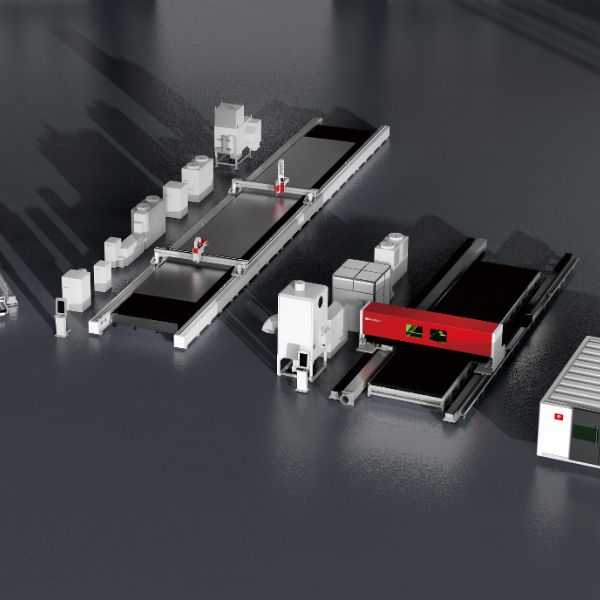

The SMART series represents the basic line of HGTECH fiber lasers for metal cutting. These machines are compact, reliable and affordable, ideal for small and medium-sized businesses dealing with the processing of sheets, tubes and mixed profiles.

Available in several options - from open models to closed systems with automatic change of work surface - SMART models offer flexibility without compromising on quality.

Call +381 64 849 45 105 10 for more information

or

SMART series - Technical characteristics

-

Laser power: 1 kW, 1.5 kW, 2 kW, 3 kW

-

Types:

-

SMART – open table

-

SMART Pro – closed system with exchangeable tables

-

SMART Plus – with automatic table change

-

SMART T – combined sheet and tube cutting machine

-

-

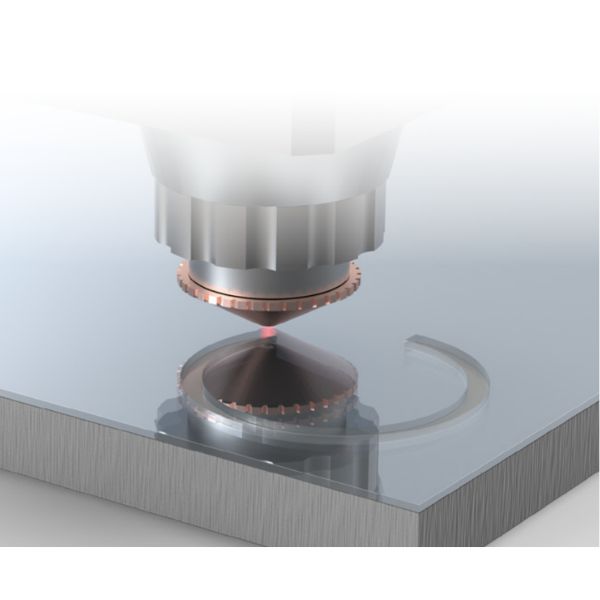

Auto-focus laser head

-

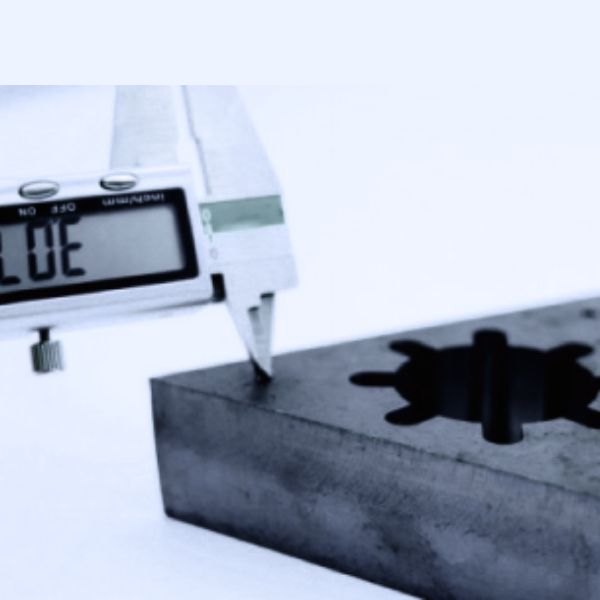

High precision and cut quality

-

Optional smoke and leftovers removal systems

-1787417813.jpg)

SMART series - Technical parameters

| MODEL | SMART 3015 | SMART 4015 | SMART 6015 | SMART 8015 |

|---|---|---|---|---|

| Cutting Area (L * W) | 3000mm * 1500mm | 4000mm * 1500mm | 6000mm * 1500mm | 8000mm * 1500mm |

| Laser Source | Fiber & 1000W - 6000W | |||

| CNC System | FSCUT | |||

| Max Moving Speed | 120 m/min, Acceleration is 1.0 G | |||

| Position Accuracy (X and Y axis) | 0.02mm | |||

| Reposition Accuracy | 0.03mm | |||

| Power Supply Requirement | 380 V 50/60 Hz | |||

SMART series - Key benefits

-

An economical entry into the world of fiber technology

-

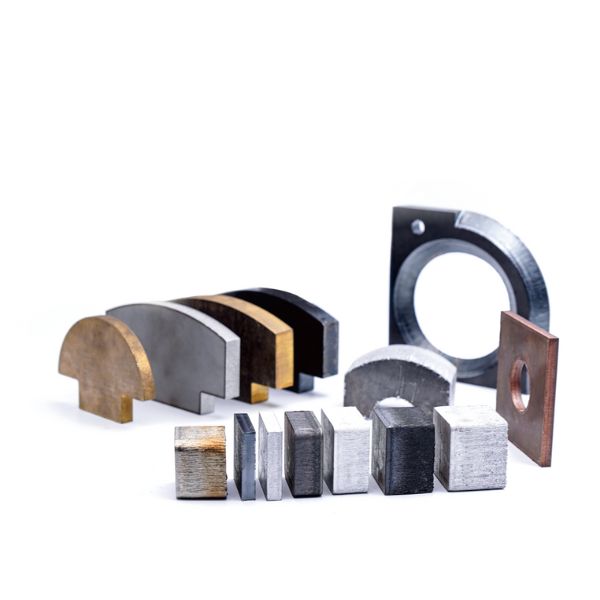

Suitable for processing steel, prochrome, aluminum

-

Easy installation and handling

-

Available models with combined processing of sheets and tubes

-

Excellent price-performance ratio

SMART series - Application

-

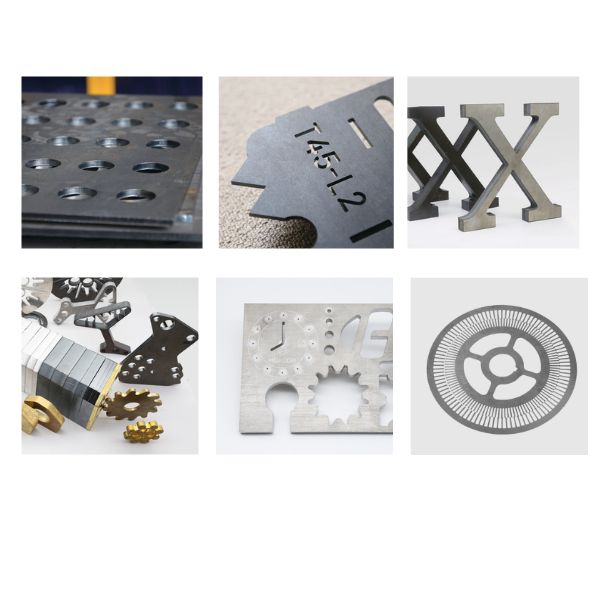

Small and medium-sized metalworking workshops

-

Light industry, production of structures, production of semi-products for furniture and advertisements

-

Workshops that want a compact but powerful solution

GF Series – High-precision fiber lasers for metal cutting

The GF series of HGTECH fiber lasers is designed for users looking for stable performance, high precision and economy in cutting various types of metals. These machines offer an ideal balance between price, capacity and energy consumption, which is why they are particularly popular in small and medium production systems with requirements for continuity and reliability.

Contact us for an offer and advice!

or

CALL +381 64 849 45 10

GF series - Technical characteristics

-

Laser power: available options from 2 kW to 6 kW

-

High cutting speed with edge quality preservation

-

Stable CNC control with automatic focusing

-

Construction optimized for rapid positioning and precise contour following

-

Low energy consumption and longer service life of components

-

It supports processing of steel, stainless steel, aluminum, brass

| Model | GF | GF | GF | GF | GF | GF | GF | ||

| 3015 | 4022 | 6025 | 3015 PLUS | 4022 PLUS | 6025 PLUS | 8025 PLUS | |||

| Processing area (mm) | X | 1500 | 2200 | 2500 | 1500 | 2200 | 2500 | 2500 | |

| Y | 3000 | 4000 | 6000 | 3000 | 4000 | 6000 | 8000 | ||

| Stroke | X | 1530 | 2230 | 2530 | 1530 | 2230 | 2530 | 2530 | |

| Y | 3050 | 4050 | 6050 | 3050 | 4050 | 6050 | 8050 | ||

| Z | 100 | 100 | 100 | 250 | 250 | 250 | 250 | ||

| Max. positioning speed (m/min) | 80 | 80 | 80 | 80 | 80 | 80 | 80 | ||

| Linkage maximum positioning speed (m/min) |

110 | 110 | 110 | 110 | 110 | 110 | 110 | ||

| Acceleration | 1.2G | 1.2G | 1.2G | 1.2G | 1.2G | 1.2G | 1.2G | ||

| Machine positioning accuracy (mm) | 0.05 | 0.05 | 0.05 | 0.05 |

|

0.05 | 0.05 | ||

| Repeated positioning accuracy (mm) |

0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | ||

| Maximum load weigh(kg) | 800 | 1800 | 2900 | 800 | 3200 | 6000 | 7500 | ||

| Machine tool weight (kg) | ≤5000 | ≤6000 | ≤8000 | ≤8000 | ≤9000 | ≤14500 | ≤17500 | ||

| Laser source | Fiber | Fiber | Fiber | Fiber | Fiber | Fiber | Fiber | ||

| 1000 | 1500 | 2000 | 3000 | 4000 | 6000 | 8000 | |||

| Power(W) | 1000 | 1500 | 2000 | 3000 | 4000 | 6000 | 8000 | ||

| Power range (W) | 100-1000 | 150-1500 | 200-2000 | 300-3000 | 400-4000 | 600-6000 | 800-8000 | ||

| Laser Ttype | Fiber | Fiber | Fiber | Fiber | Fiber | Fiber | Fiber | ||

| Max cutting thickness (mm) | |||||||||

| Carbon steel (mm) | 10 | 14 | 16 | 20 | 20 | 25 | 30 | ||

| Stainless steel (mm) | 5 | 6 | 8 | 12 | 16 | 20 | 25 | ||

| Aluminum alloy (mm) | 2 | 4 | 6 | 10 | 20 | 16 | 25 | ||

.jpg)

GF series - Key benefits

-

An ideal solution for serial production with moderate capacities

-

Precise cutting without the need for additional processing

-

Possibility of upgrading and integration into existing systems

-

Quick return on investment thanks to low exploitation costs

-

Reliable operation in multi-shift mode

.jpg)

GF series - Application

-

Production of parts for mechanical engineering and electrical industry

-

Production of metal housings, components and tools

-

Sheet metal processing in the auto industry, ventilation, construction

.jpg)

MARVEL series - Fiber lasers for highly efficient metal cutting

The MARVEL series represents the pinnacle of technology in the segment of fiber lasers for metal cutting. It is intended for companies looking for a stable, automated and extremely powerful system for metal processing of large thicknesses and dimensions.

With a power of up to 30 kW, advanced protection functions and the possibility of integration with smart factories, MARVEL machines are ideal for mass production, the automotive industry, energy and large metal processing plants.

Contact us for configuration according to your needs

or

call + 381 64 849 45 10

MARVEL series - Technical characteristics

-

Laser power: from 12 kW to 30 kW

-

Types: MARVEL PRO and MARVEL PLUS

-

Maximum positioning speed: up to 168 m/min

-

Acceleration: up to 3.0 G

-

Remote diagnosis and smart collision protection

-

Closed system with MES interface for automatic management and monitoring

-

Possibility of exchangeable table for continuous production

| MODEL | MARVEL Plus 3015 | MARVEL Plus 4022 | MARVEL Plus 6255 | MARVEL Plus 8255 | MARVEL Plus 10225 | MARVEL Plus 12025 | |

| Processing area (mm) | X | 3100 | 4060 | 6080 | 8080 | 10080 | 12080 |

| Y | 1530 | 2225 | 2570 | 2570 | 2570 | 2570 | |

| Z | 280 | 280 | 280 | 280 | 280 | 280 | |

| Max. positioning linkage speed | 140 m/min | 140 m/min | 140 m/min | 140 m/min | 140 m/min | 140 m/min | |

| Acceleration | 2.0G | 2.0G | 2.0G | 2.0G | 2.0G | 2.0G | |

| Positioning accuracy | 0.05mm | 0.05mm | 0.05mm | 0.05mm | 0.05mm | 0.05mm | |

| Repeated positioning accuracy | 0.025mm | 0.025mm | 0.025mm | 0.025mm | 0.025mm | 0.025mm | |

| Laser power | 12000-20000W | ||||||

| MODEL | MARVEL Pro 3015 | MARVEL Pro 4022 | MARVEL Pro 6255 | MARVEL Pro 8255 | MARVEL Pro 10225 | MARVEL Pro 12025 | |

| Processing area (mm) | X | 3100 | 4100 | 6100 | 8100 | 10080 | 12100 |

| Y | 1530 | 2225 | 2570 | 2570 | 2570 | 2570 | |

| Z | 350 | 350 | 365 | 365 | 365 | 365 | |

| Max. positioning linkage speed | 169 m/min | 169 m/min | 169 m/min | 169 m/min | 169 m/min | 169 m/min | |

| Acceleration | 3.0G | 3.0G | 3.0G | 3.0G | 3.0G | 3.0G | |

| Positioning accuracy | 0.05mm | 0.05mm | 0.05mm | 0.05mm | 0.05mm | 0.05mm | |

| Repeated positioning accuracy | 0.025mm | 0.025mm | 0.025mm | 0.025mm | 0.025mm | 0.025mm | |

| Laser power | 30000W | ||||||

MARVEL series - Key benefits

-

High productivity with non-stop working mode

-

Laser head with automatic focusing

-

Compatibility with automated warehouses and robotization

-

Stability and precision even in long-term work

-

Reduced maintenance and energy consumption costs

MARVEL series - Application

-

Mass production of metal structures

-

Production of components for cars, shipbuilding, energy sector

-

Processing of thick steel sheets of large dimensions

-

Factories with requirements for automation and monitoring

WALC Series – Industrial fiber lasers for cutting large formats

The WALC series represents the most robust line of HGTECH fiber lasers, specially developed for the processing of large and heavy metal formats. With powers up to 30 kW, double gantry drive and high precision, WALC machines are indispensable in heavy industry and large metalworking systems.

The WALC series includes several versions that allow users to choose between maximum stability (WALC-F) and high speed with a lighter construction (WALC-P).

Contact us for an offer or advice

or call +381 64 849 45 10

WALC series - technical characteristics

-

Laser power: from 12 kW to 30 kW

-

Types:

-

WALC-F – standard, stable construction with dual drivestandardna, stabilna konstrukcija sa dvostrukim pogonom

-

WALC-P – lightweight construction for fast processing

-

-

Max. positioning speed: up to 150 m/min

-

Acceleration: up to 2.5 G

-

The gantry construction enables the processing of extremely large dimensions

-

Software with support for automatic nesting and MES integration

| WALC P SERIJA | Osnovni parametri | |

| Basic Specification | Laser Power | 6000-30000W |

| Focal Length | F200 ~ F300mm automatic focus | |

| Operativni sistem | Windows 10 (Engleski) | |

| CNC System | FARLEY-A, FARLEY-H | |

| Display | 23.6-inch touch display (mouse operation supported) | |

| Machining Range Vertical Cutting | Metal material arbitrary shape workpiece cutting, marking, etc. | |

| Bevel cutting processing range | Carbon steel/stainless steel/aluminum V/Y/X/K cutting at an angle of ±45° | |

| Processing Capability | Carbon Steel Plate Cutting Thickness(O2) | Vertically cut MAX 80mm / Bevel cut max 30mm |

| Stainless Steel Plate Cutting Thickness(N2) | Vertically cut MAX 100mm / Bevel cut MAX 25mm | |

| Aluminum Alloy Plate Cutting Thickness(N2) | Vertically cut MAX 100mm / Bevel cut MAX 20mm | |

| Processing Stroke | X Axis Stroke | MAX 50m(customizable) |

| Y Axis Stroke | MAX 6m(customizable) | |

| Z Axis Stroke | 300mm | |

| Positioning Accuracy | X Axis Positioning Accuracy | 0.1mm/10m(≤10m),0.2mm/full length |

| YX Axis Positioning Accuracy | 0.05mm | |

| X Axis Repeated Positioning Accuracy | 0.05mm/10m(≤10m),0.1mm/full length | |

| X Axis Repeated Positioning Accuracy | 0.03mm | |

| Processing Speed | Maximum Acceleration | 0.6G |

| X/Y Axis Maximum Positioning Speed | 40m/min | |

| X/Y Axis Maximum Linkage Positioning Speed | 56m/min | |

| Power | Number of Phases | 3 |

| Rated Voltage | 380V | |

| Frequency | 50Hz | |

| Total Power Supply Protection Level | IP54 | |

| Project | Main Parametrs | |

| Basic Specification | Laser Power | 6000-30000W |

| Focal Length | F200 ~ F300mm automatic focus | |

| Operating System | Windows 10(Chinese and English) | |

| CNC System | FARLEY-A, FARLEY-H | |

| Display System | 23.6-inch touch display (mouse operation supported) | |

| Machining Range Vertical Cutting | Metal material arbitary shape workpiece cutting, marking, etc. | |

| Processing Capability | Carbon Steel Plate Cutting Thickness(O2) | Vertically cut MAX 80mm |

| Stainless Steel Plate Cutting Thickness(N2) | Vertically cut MAX 100mm | |

| Aluminum Steel Plate Cutting Thickness(N2) | Vertically cut MAX 100mm | |

| Processing Stroke | X Axis Stroke | MAX 50m(cutomizable) |

| Y Axis Stroke | MAX 6m(cutomizable) | |

| Z Axis Stroke | 250mm | |

| Processing Accuracy | X Axis Positioning Accuracy | 0.1mm/10m(≤10m),0.2mm/full length |

| YX Axis Positioning Accuracy | 0.05mm | |

| X Axis Repeated Positioning Accuracy | 0.05mm/10m(≤10m),0.1mm/full length | |

| Y Axis Repeated Positioning Accuracy | 0.03mm | |

| Processing Speed | Maximum Acceleration | 0.6G |

| X/Y Axis Maximum Positioning Speed | 40m/min | |

| X/Y Axis Maximum Linkage Positioning Speed | 56m/min | |

| Power | Number of Phases | 3 |

| Rated Voltage | 380V | |

| Frequency | 50Hz | |

| Total Power Supply Protection Level | IP54 | |

WALC Series - Key Benefits:

-

Suitable for cutting large metal plates and boards

-

Stability of operation at high loads

-

High efficiency and processing speed

-

Advanced security and diagnostic solutions

-

Compatibility with automatic feeding and sorting systems

WALC Series - Application

-

Heavy metal processing industry

-

Production of constructions for shipbuilding, energy and infrastructure

-

Cutting thick-walled sheets of large dimensions