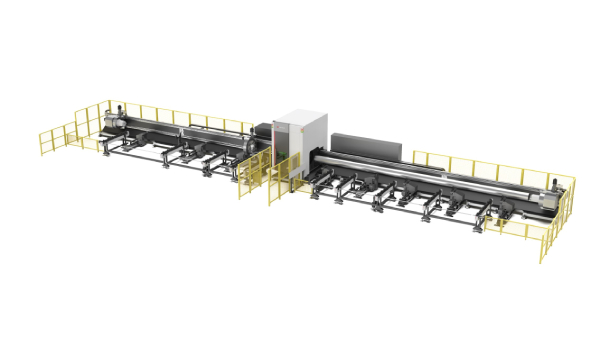

Tube Laser Cutting Machine – Precise and fast processing of metal tubes and profiles

HGTECH tube lasers cutting machines enable fast, stable and high-precision processing of tubular and profiled materials - from standard metal pipes to complex shapes with multiple sections. Designed for automated and continuous production, these systems combine power, flexibility and precision in a unique solution.

With the optional BEVEL angle cutting system, as well as automated modules for loading and unloading, HGTECH tube systems are the right choice for companies working in the construction, transport, furniture and ventilation industries.

If you are interested, send an inquiry

or call 064 849 45 10

Tube Laser Cutting Machine - Technical characteristics

-

Laser power: from 3 kW to 12 kW

-

Processing lengths: 6 m / 9 m / 12 m

-

Supported shapes: round, square, rectangular tubes, profiles

-

System for automatic centering and clamping of tubes

-

BEVEL cutting at an angle of ±45° – ideal for welded joints

-

Optional automation: material loading and unloading

-

CNC software with graphical simulation and cut optimization

Tube laser cutting machines - Key benefits

-

Precise cutting without the need for additional processing

-

High productivity with minimal waste

-

Suitable for serial production and multi-shift work

-

Quick program change and flexibility in tube dimensions

-

Possibility of integration into automated production lines

Application

-

Metal structures and assembly halls

-

Transport industry (chassis)

-

Production of furniture and advertising structures

-

Ventilation and piping systems

.jpg)